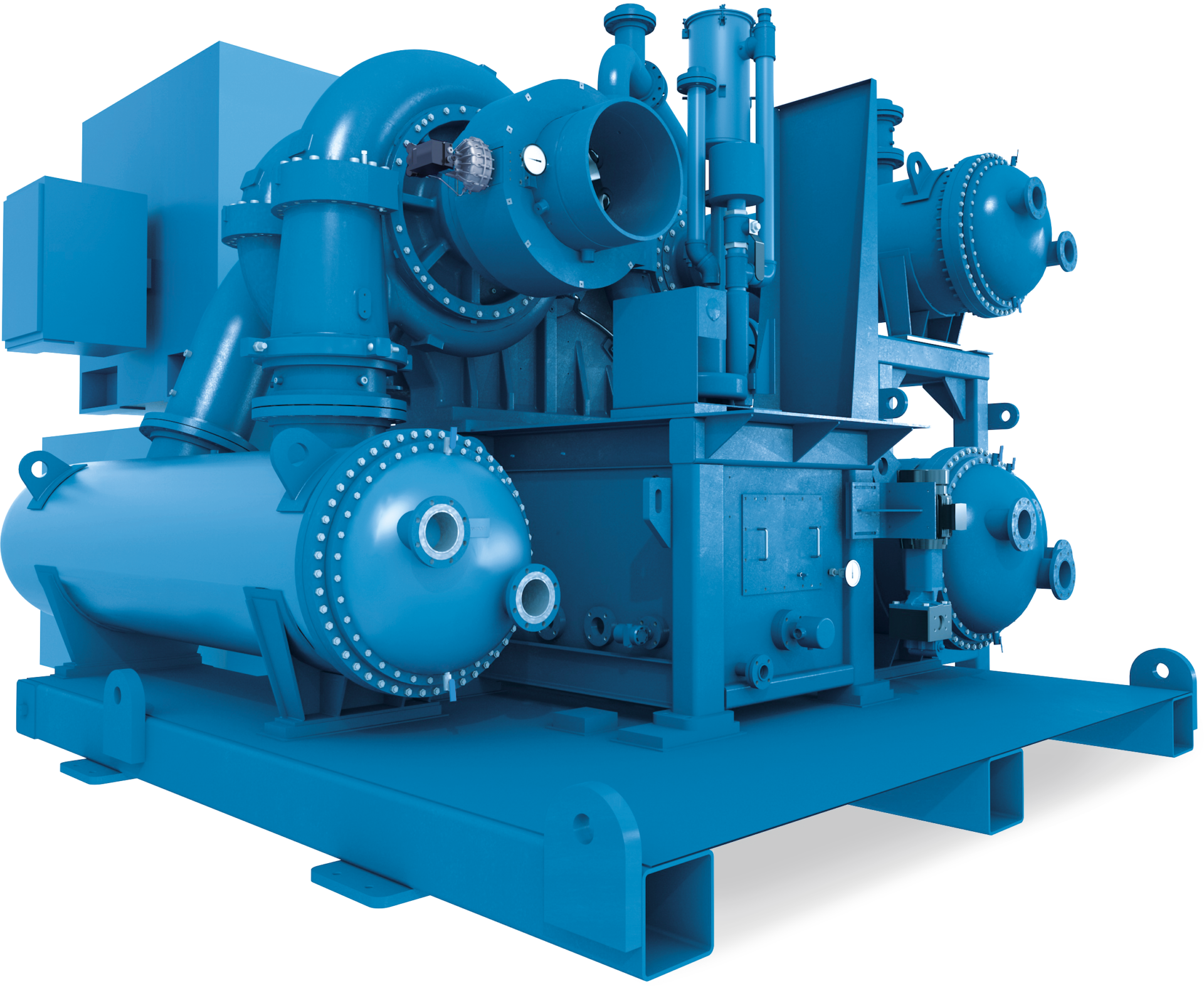

Simply Superior Design

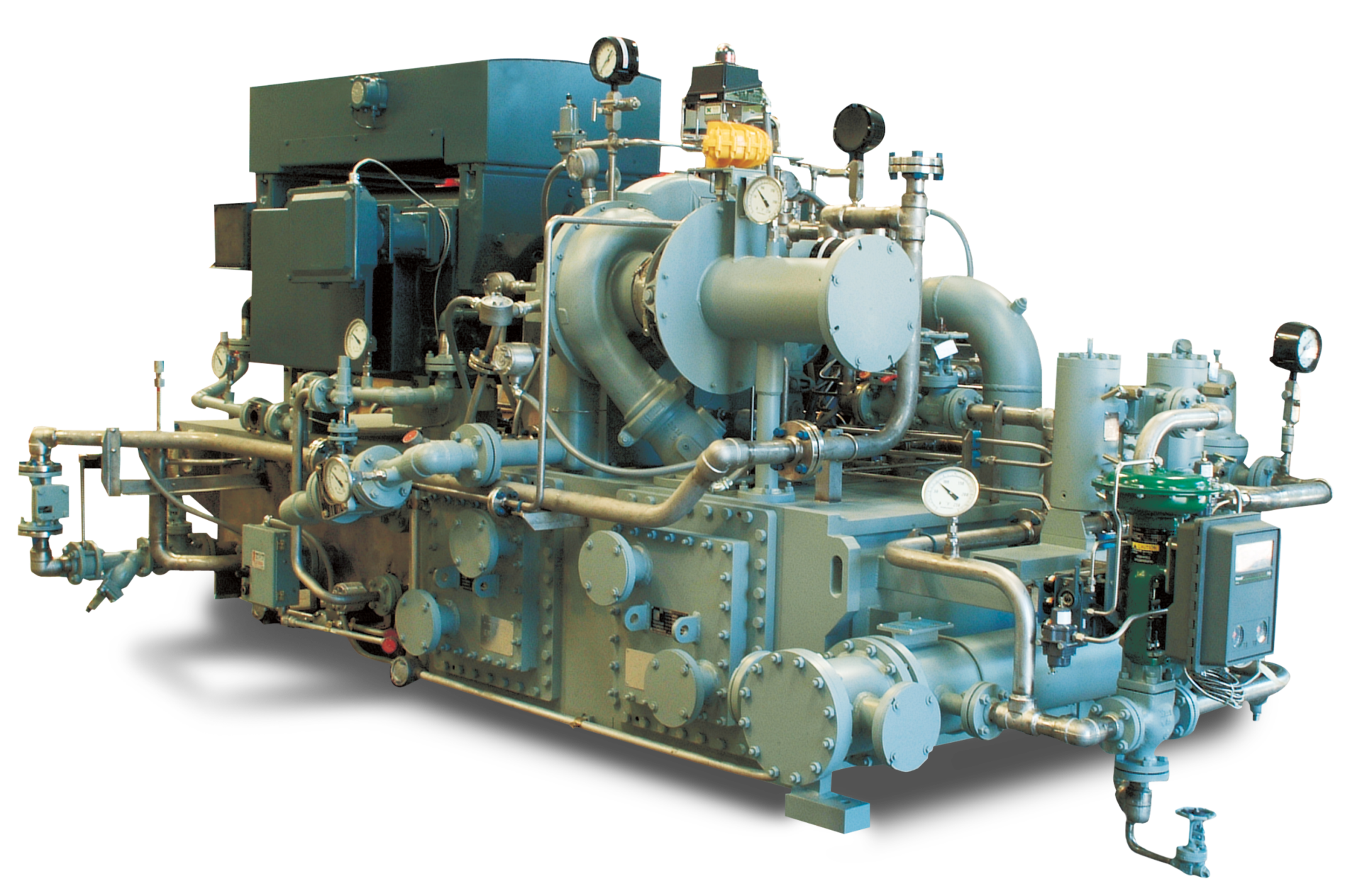

PAP Plus compressors are built on a simple, centrifugal design that delivers superior reliability and performance. The only moving parts are the bull gear and the rotors. With no lubricated parts in the air passages, the airstream is oil-free.

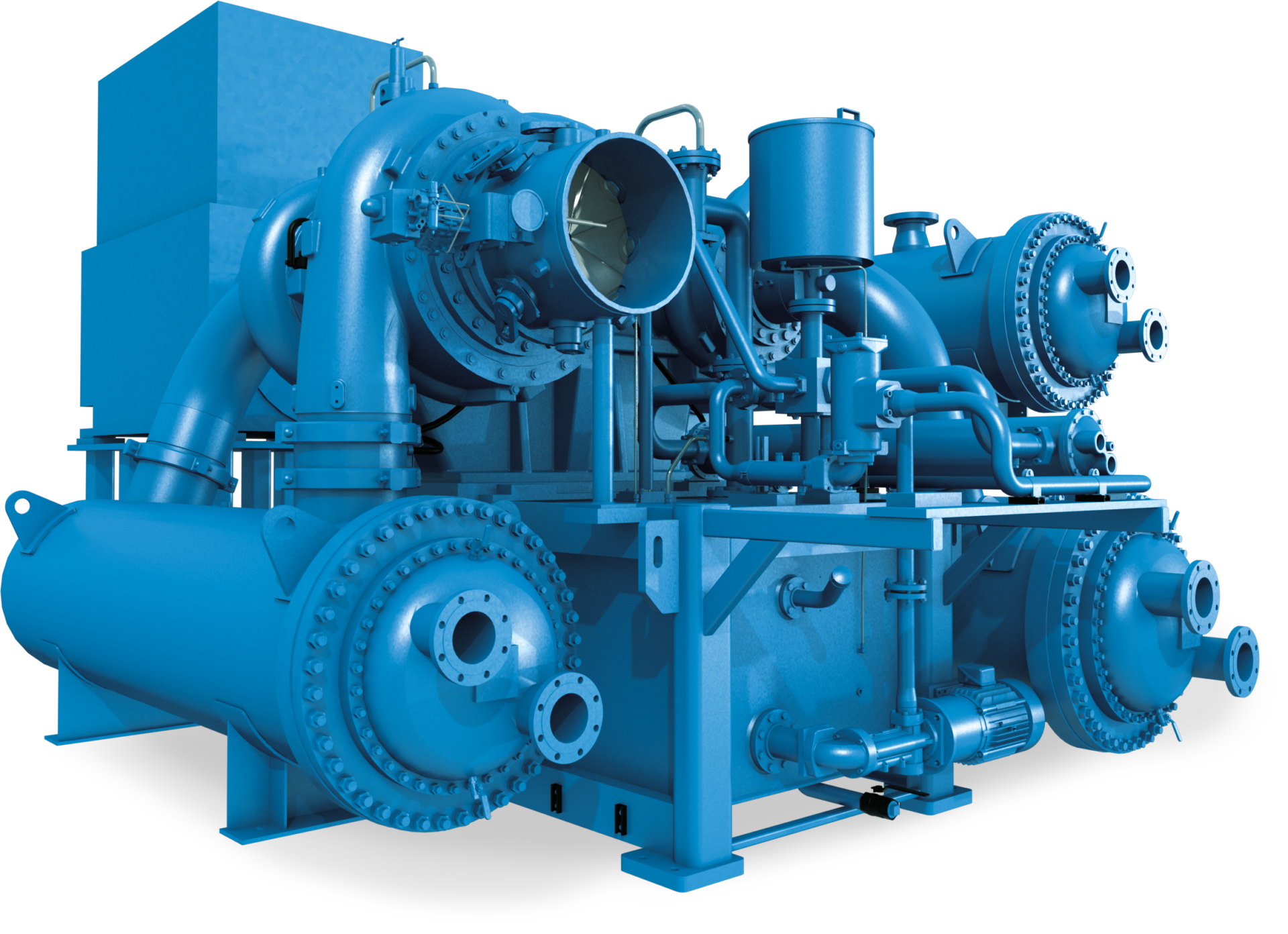

Intercoolers Minimize Power Loss

Effective intercoolers are a key to compressor operating performance and energy efficiency. All FS-Elliott packaged air compressors feature compact, highly efficient heat exchangers that provide minimum pressure loss, high heat-transfer efficiency, and fast and simple cleaning of the straight-through tube bundles. Phenolic (fluoropolymer) coatings are also available for extreme duty applications.

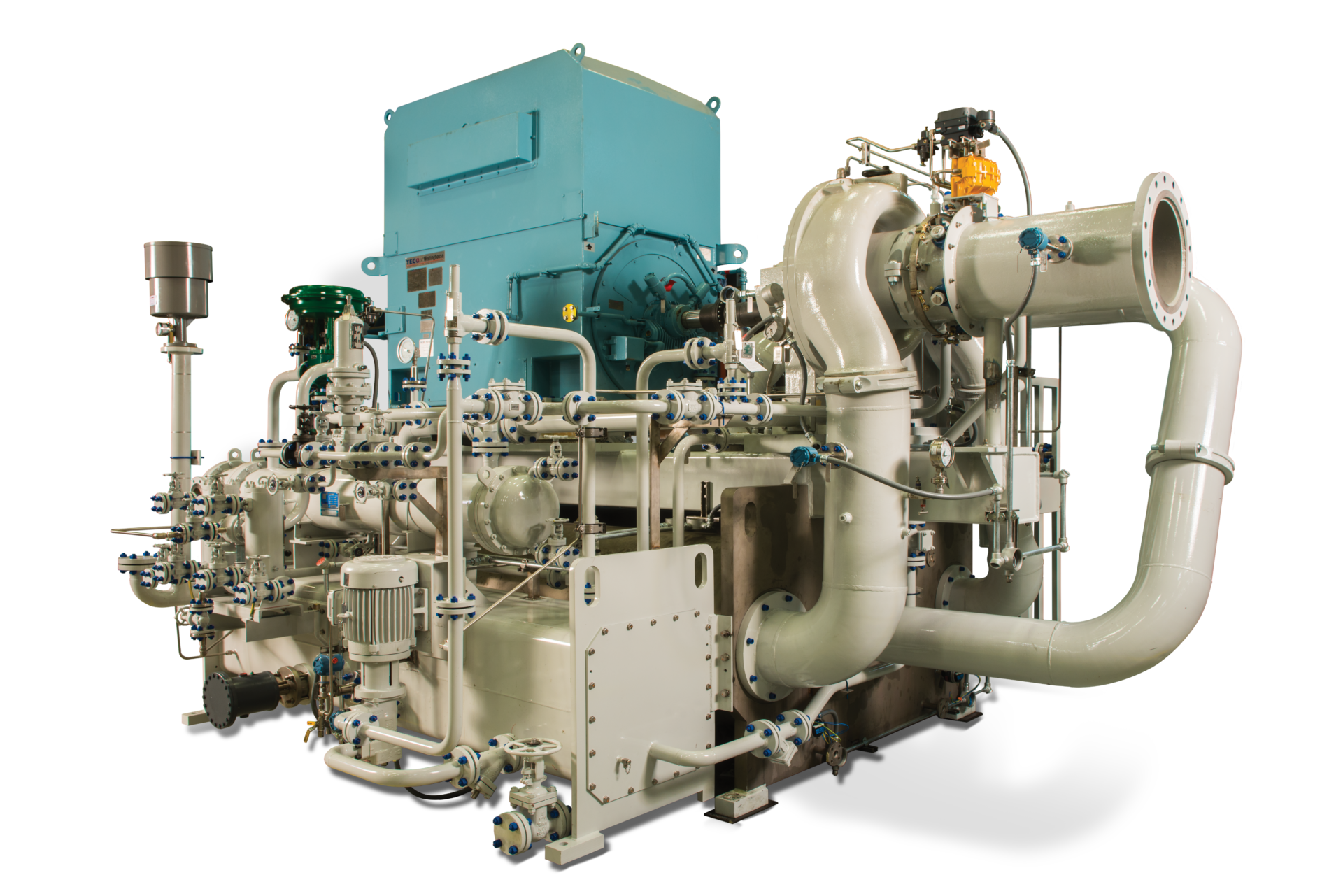

Impeller, diffuser, and scroll designs are uniquely sized to meet your specific needs in order to provide peak efficiency and large operating ranges. Superior impeller designs feature optimum blade loading and shroud profiling for your required performance level, which minimizes skin friction, incidence, recirculation, and other loss mechanisms inherent in impeller performance.

FS-Elliott engineers use the latest engineering design software to improve aerodynamic performance and enhance product design. Computational Fluid Dynamics (CFD) is used to perform complex flow analysis of aerodynamic components to increase stage efficiencies and optimize compressor performance.

Adjustable Inlet Guide Vane

Adjustable inlet guide vanes control inlet flow to save energy. The guide vanes are automatically positioned in response to ambient air and system demand changes. They reduce the flow through the compressor by imparting a pre-swirl to the incoming airstream. This pre-swirl controls the work of the first stage impeller, adjusting the power and throughput to match system demand. By controlling the amount of air being compressed (and consequently the power consumed), the inlet guide vane efficiently adjusts to plant conditions and load variations to conserve energy.

Accessibility & Maintenance

The gearing, intercoolers, aerodynamic parts, lubrication system, and control system are all independently accessible. Maintenance of any one of these items does not require disassembling other components or exchanging large assemblies. Unlike other compressors, the unique PAP horizontally split design was meticulously designed to provide quick and easy local maintenance. Components do not need to be sent back to the factory. Compare this time-efficient procedure with other compressor designs that require days to perform the same tasks.